Questions & Answers

- Q. Hi, I recently inherited one of your tools and I'm hoping you can tell me what it is? I've attached a photo. Many thanks, Kim, Silversmith.

- Date: 02 Nov 2021

-

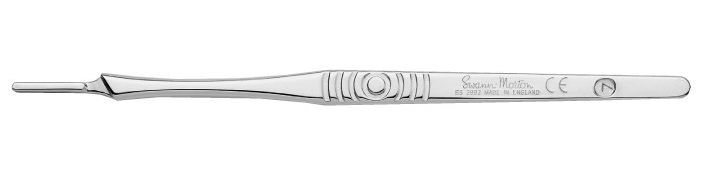

EnlargeHi Kim. It looks like someone has filed/ground away the fitment end of an old Nickel Alloy Surgical handle. The current versions are stainless steel and look like the image below your handle when supplied. We have no idea why they would have a use for the handle in this format.

- Q. Just coming back to marquetry after many years and want to get the right knife handle and blades for cutting thin marquetry veneers. Can you advise please?

- Date: 08 Apr 2021

-

Enlarge Hi Geoff, Thank you for your question. I don’t think you can go far wrong with the No.3 Surgical handles and our 10A surgical blade or the No.11/11P if you are looking for a finer point and working with light weight materials / veneers. We will have now published [An Expert’s Guide to Craft Knives](https://www.craftknives.co.uk/guide.php) on our craft website so you may find that interesting as well. - Q. How do I change the blade on my Craft Tool Knife ?

- Date: 11 Aug 2020

-

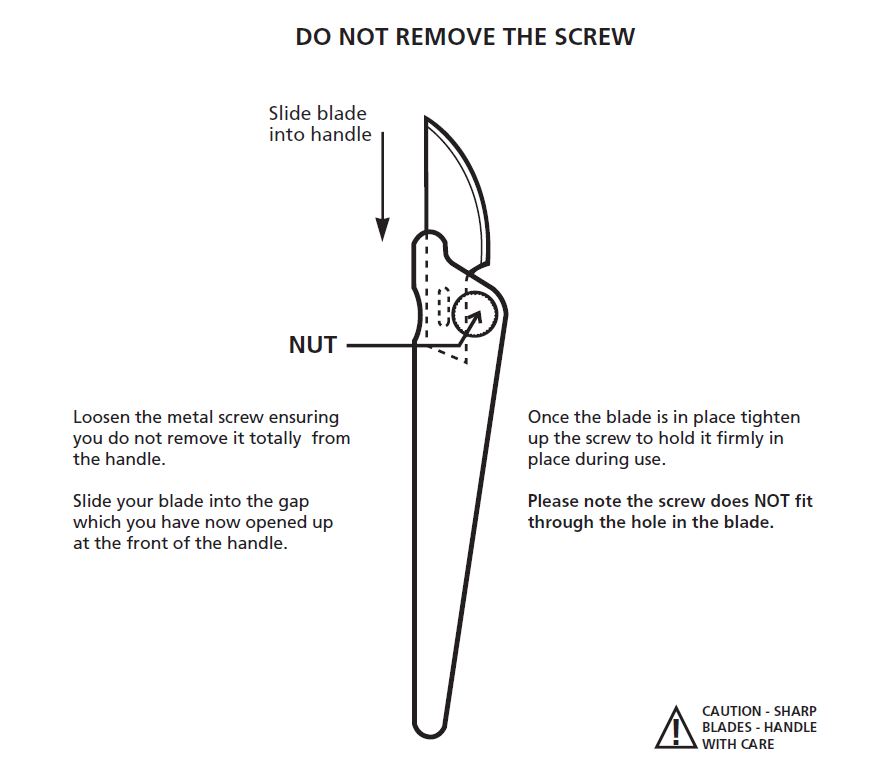

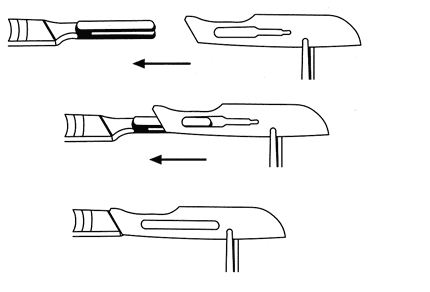

Enlarge Loosen the metal screw ensuring you do not remove it totally from the handle. Slide the blade into the gap which you have now opened up at the front of the handle. Once the blade is in place tighten up the screw to hold it firmly in place during use. Please note the screw does NOT fit through the hole in the blade. - Q. Is the Supatool handle stainless steel?

How thick are the Supatool blades S, T, V, W?

Are they the same blades as for the Major scalpel handle? (they look the same)

Thanks - Date: 12 Jun 2020

-

Enlarge Dear Oneth, Thank you for your questions. The Supatool handle is not Stainless Steel it is a powder coated metal alloy. The thickness of the blades is 0.635 mm. Yes, you are correct the Supatool and Swann-Major blades are the same size and shape, however the latter are supplied sterile for heavy duty surgical procedures in areas such as Orthopaedics. If you have any other questions then please do not hesitate to contact us - Q. Do you have rectangular blades, to use as a spoke-shave for shaping wood ?

I saw a how to article from Lee Valley Tools using handmade handles & I wanted to try it. - Date: 11 Jun 2020

-

Enlarge Hi Donald, If you are looking for rectangular type blades for shaving then I suggest you visit the website of our sister company Jewel Blade Limited as they may have something suitable in their range. The website address is : [www.jewelblade.co.uk](https://www.www.jewelblade.co.uk) Thank you for your enquiry - Q. I am thinking of getting a Swann-Morton ACM Modelling knife set for hobby use. Is there a safe way of ejecting and re-inserting new blades for this set?

- Date: 07 Jun 2020

-

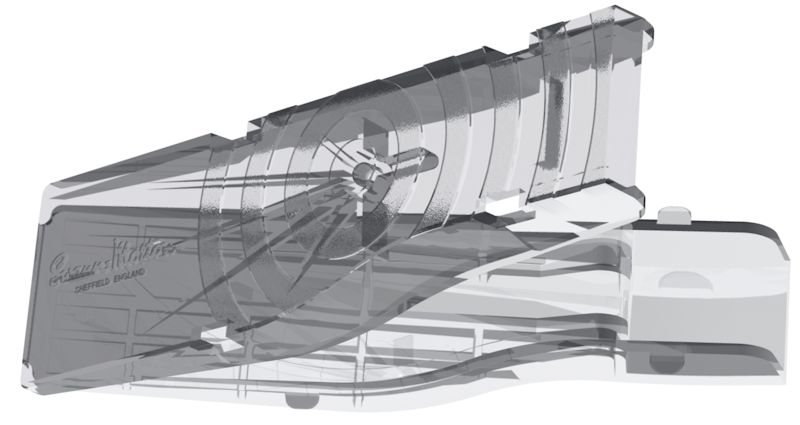

Enlarge Dear Margaret, thank you for your question about fitting and removing blades from the ACM range handles. You can download the instructions [here](https://www.swann-morton.com/uploads/How-do-I-change-the-blades-on-my-ACM-Knife-_.pdf) or click on the image. However, if you don’t feel comfortable using your fingers on the blade then you could use a small pair of pliers to grip the blade when slotting it into and when removing it from the Collet (Knurled collar) fitment. Make sure the collet is fully opened as this will make the fitment and removal easier and make sure you do not grip across the cutting edge during fitment as this will have a detrimental effect on the cutting performance. If you have any additional questions then please do not hesitate to contact us. - Q. Hello: I hope you are all well. I am in Canada your are in England. Just read an Lee Valley Tools interesting article by a wood worker recommending your SM O1 scalpel.

Paul Sellers wood working teacher in England highly recomends the blade.

On your web site it is not distributed in Canada.... no links or maps. I would like to make a set of 20 knives for Christmas.... ordering from the UK dicey during these.

Please give me some direction who has the in stock. Cheers Stay well Jerry Walker Alliston Ontario Canada - Date: 05 May 2020

- ** answered via email **

- Q. Hi,

I have lost the handle I use with my No. 26 and 22A Blades and cannot recall the number of the handle. It was a stainless handle similar to the No. 3 but larger. Could you advise please. - Date: 24 Feb 2020

- Hi Alan, It would have been the No.4 handle for as you say it is bigger than the No.3 handle and has a larger fitment which corresponds with the larger size blades like the 22A and 26.

- Q. Just coming back to marquetry after many years and want to get the right knife handle and blades for cutting thin marquetry veneers. Can you advise please?

- Date: 17 Oct 2019

-

Enlarge Hi Geoff, Thank you for your question. I don’t think you can go far wrong with the No.3 Surgical handles and our 10A surgical blade or the No.11/11P if you are looking for a finer point and working with light weight materials / veneers. We will soon be publishing an “Expert’s Guide to Craft Knives" on our craft website [craftknives.co.uk](https://www.craftknives.co.uk) so you may find that interesting as well. - Q. Hi, I have a Swann-Morton craft knife set. The one in the blue case. It has all the blades but these are getting quite blunt. Also one of the handles no longer tightens up to hold the blade in place. Can I get my blades sharpened or am I best purchasing a new set? Thanks, Rachael

- Date: 20 Aug 2019

- Hi Rachel, Thank you for your enquiry. The blades will go blunt over time with usage and this can happen quite quickly if you are cutting hard materials or cutting down onto a hard surface such as glass. The collet fitting on the handles again can wear over time depending on usage. You could purchase a new ACM set or individual ACM handles with the blade shapes that you use most, separately. You can get these online at www.scalpelsandblades.co.uk via [this link](https://www.scalpelsandblades.co.uk/range_24_swann-morton-acm-blades-and-handles.php) I hope this helps.

- Q. Hello, I have an old brass Handi-Tool knife, which I see from your website has been replaced with a stainless steel version. Please can you advise whether the blades for the stainless steel handle would be compatible with my brass handle?

Many thanks, Sharon - Date: 15 Aug 2019

- Hi Sharon. Yes if the blades fit the brass craft handle they will be compatible with the new Stainless Steel version.

- Q. How do I change the blades on my ACM Knife?

- Date: 04 Jul 2019

-

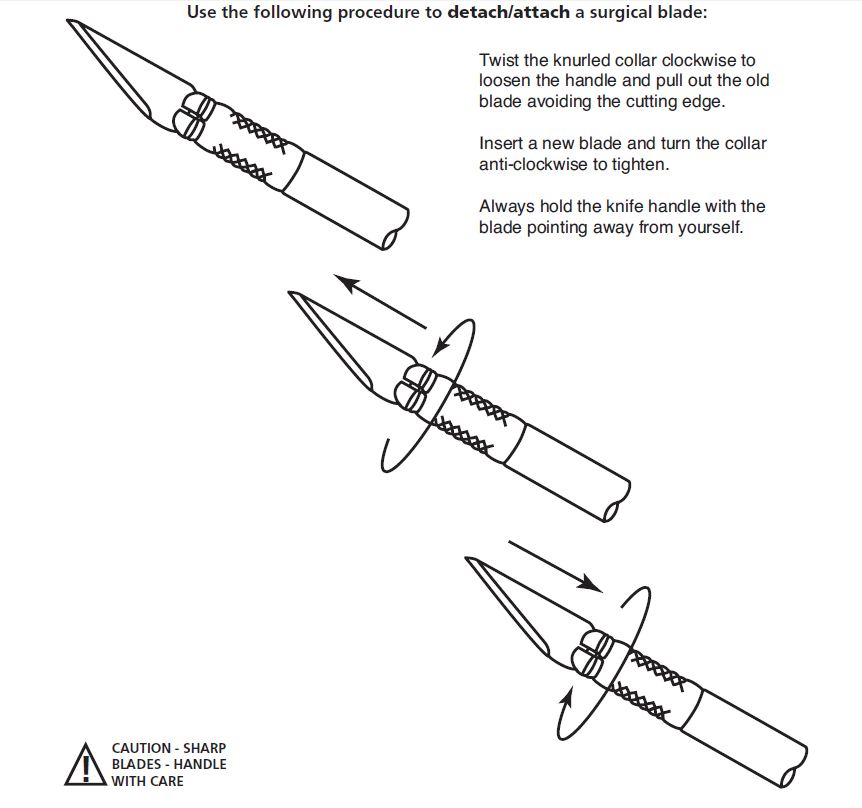

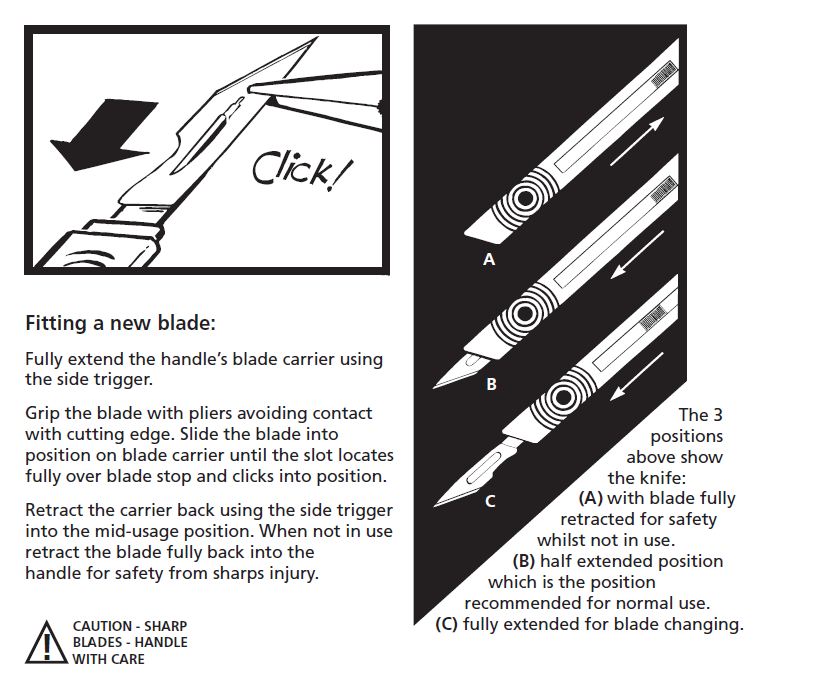

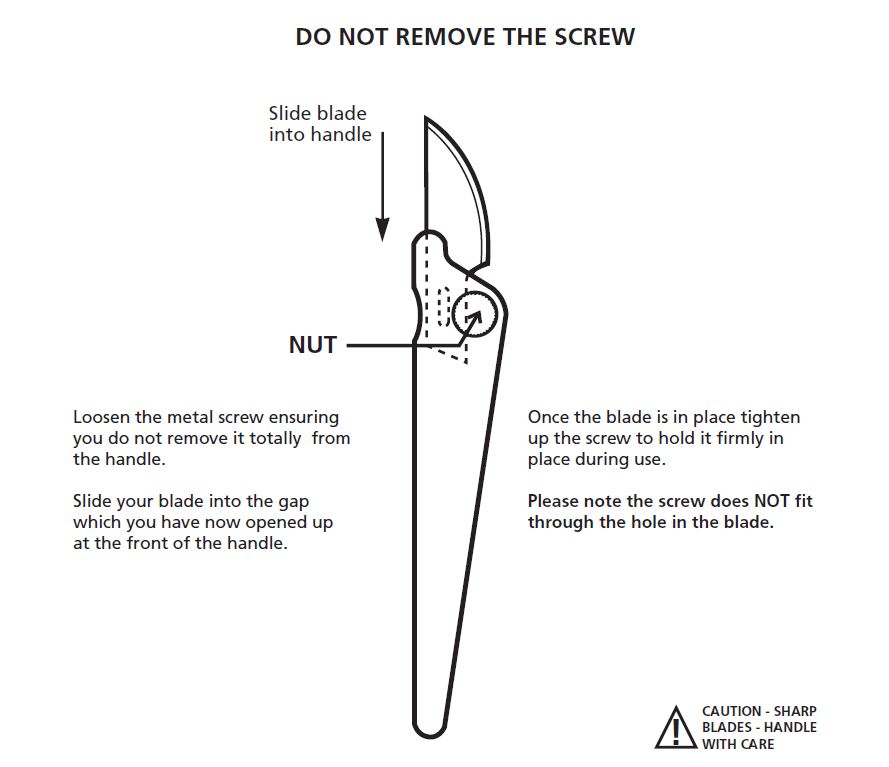

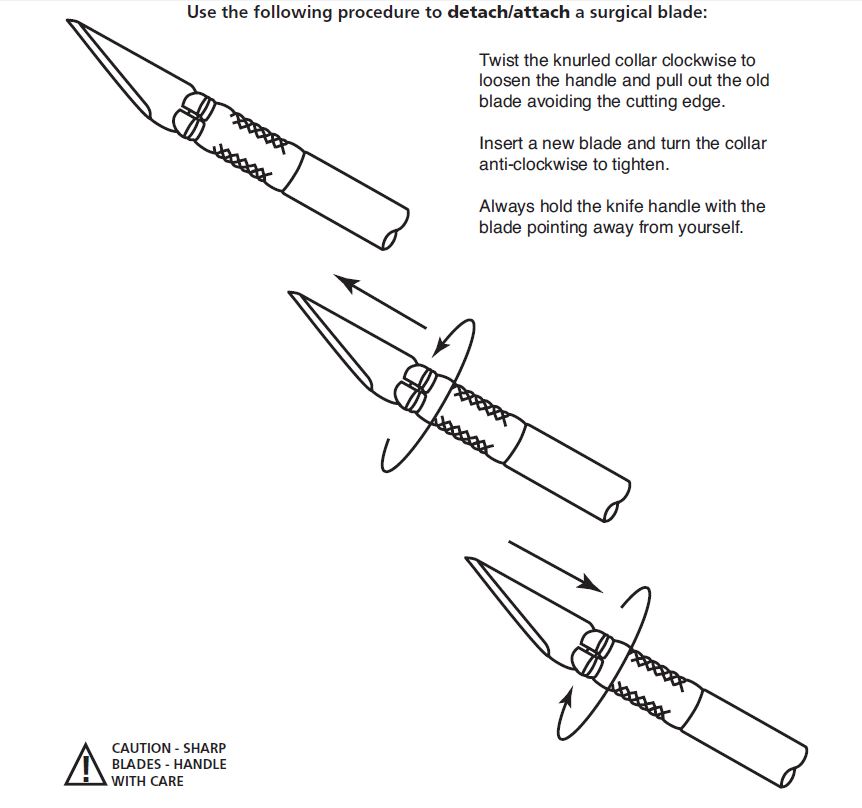

Enlarge Twist the knurled collar clockwise to loosen the handle and pull out the old blade avoiding the cutting edge. Insert a new blade and turn the collar anti-clockwise to tighten. Always hold the knife handle with the blade pointing away from yourself. - Q. How do I fit a blade to my Retractaway Knife ?

- Date: 04 Jul 2019

-

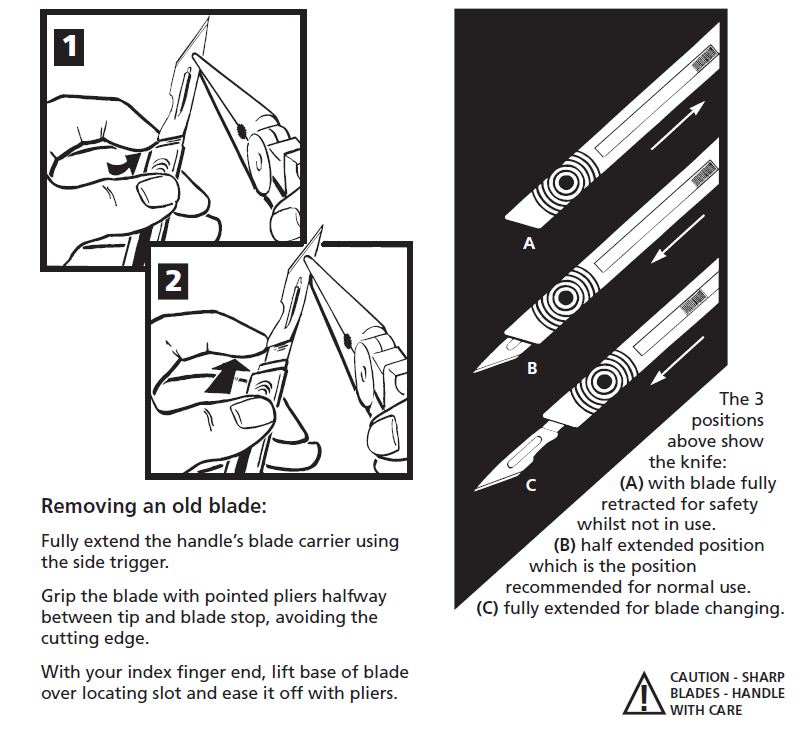

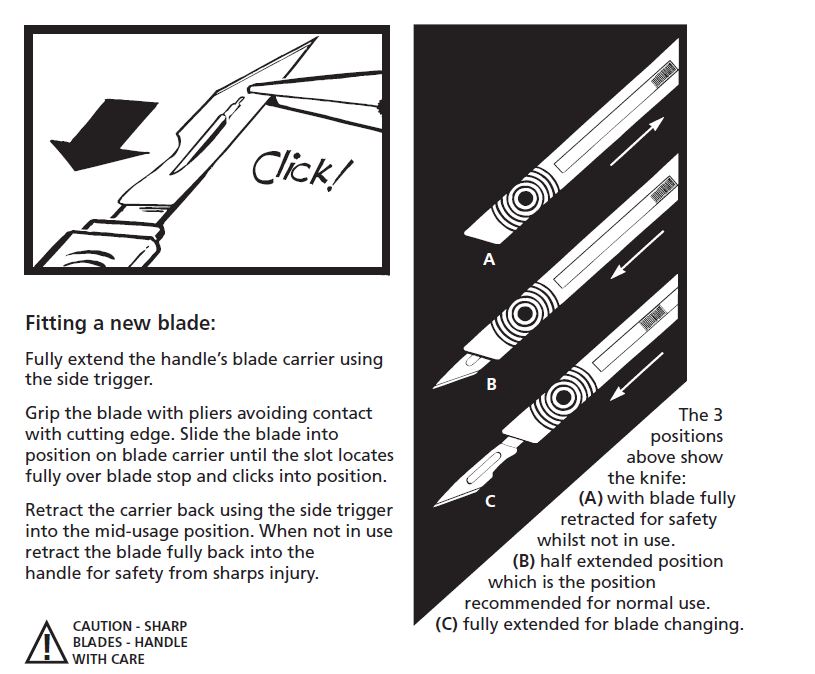

Enlarge Fully extend the handle's blade carrier using the side trigger. Grip the blade with pliers avoiding contact with cutting edge. Slide the blade into position on blade carrier until the slot locates fully over blade stop and clicks into position. Retract the carrier back using the side trigger into the mid-usage position. When not in use retract the blade fully back into the handle for safety from sharps injury. - Q. Hello, are your handles made from solid stainless blanks or are they pressed/cast out of pot metal?

- Date: 10 Mar 2019

- Hi Pete, the handles are actually made via a complex stainless steel injection moulding process.

- Q. Hi, I would like to know the material of SM9303.

Thanks, Katie. - Date: 03 Jan 2019

-

Enlarge Hi Katie, thanks for your question. Our Product Ref 9303 are our ACM No. 11 blades (which come boxed in 50's). They are manufactured by Swann-Morton in Sheffield from 1% carbon steel and they are compatible with our [ACM No. 1 Handle](https://www.craftknives.co.uk/product/acm-handle-1). - Q. Hi. What is the most suitable blade and handle for sharpening artists' wood encased pencils (carbon, charcoal, graphite, etc.)? Thanks, Anne

- Date: 25 Oct 2018

-

Enlarge Hi Anne, to be honest if you are looking to sharpen to a fine point then a surgical blade like the 10A on a No.3 Handle would definitely do the job however we would imagine the blade could dull very quickly given the composition of the material you are shaping. We would try one of our Trimaway knives. You have the convenience of the blade already being attached to the red handle and with a protective cap for when the knife is not in use. The blade is a mirror image of one of our surgical blade shapes the 25A, yet it is manufactured from a slightly thicker material so may provide more durability when sharpening your pencils. You can buy these in a box of 50, however a more convenient option are the point of sale display cards which carry three knives and should be available through the likes of Hobbycraft or online via Scalpels and Blades. We hope this answers your question. - Q. Hi. Just wondering what the difference is between the Supatool and the SM00 fixed metal handle? These seem to be the same thing? Thanks, Tristan

- Date: 20 Aug 2018

-

Enlarge Thanks for your question Tristan, The Supatool handle & SM00 Handle are for different ranges of blades (please see our website link below) The Supatool handle fits Supa/Major S, T, V & W blades [Supatool Handle Blades](https://www.craftknives.co.uk/product/supatool) The SM00 Handle fits SM01, SM02, SM03 & SM04 range. [SM00 Handle Blades](https://www.craftknives.co.uk/product/sm00-handle) Should you require any further assistance please don’t hesitate to contact us again. - Q. The knives have a number, what is the number for? At our hospital we use 11, 15, 10 and 21. Is it the curve of the blade or something else? Thanks, Marianne

- Date: 12 Jul 2018

- Hi Marianne, if you go to the Interactive section of the surgical site at [www.swann-morton.com](www.swann-morton.com) and then in FAQ’s there are a lot of answers on the history of the company and blades in general which you may find of interest. In answer to your question: The two piece scalpel with a metal handle and detachable blades was designed and patented in 1915 by Morgan Parker in the USA. The American College of Surgeons encouraged him to go into large scale manufacture and having contacted medical suppliers C.R.Bard through the Yellow Pages they expressed an interest in the project and supplied the capital. The company Bard-Parker was formed. It was Parker who numbered his handles one to nine and his blades from 10 to 20. These have only persisted in part with additional numbers and 'A' numbers being added especially after the patent expired in 1935. (John Kirkup, MD FRCA, Honorary Curator, Historic Instrument Collection, Royal College of Surgeons of England; Journal of Medical Biography, Volume 13, November 2005)

- Q. Are there any Swann-Morton blades that have a single bevel cutting edge? I would like to cut thin sheet material exactly next to a straight edge with a perfect vertical cut. Having a double bevel leaves an angled profile edge very slightly offset, which I need to avoid. Thanks! Nick

- Date: 07 Jul 2018

-

Enlarge Hi Nick, we do offer two blades in our fine blade surgical range SM61(SB) and SM62(SB) that can be ordered under codes [5911](https://www.swann-morton.com/product/68.php) and [5912](https://www.swann-morton.com/product/69.php) accordingly which are single bevel so like very small chisels. These fit one of four “Fine” handles that vary in length depending on user requirements. Alternatively you might like to try the [ACM 18 blades](https://www.craftknives.co.uk/product/acm-handle-2#spare-blades) (Code 9318) which fits the [ACM No.2 handle](https://www.craftknives.co.uk/product/acm-handle-2). Give them a try and let us know how you get on. - Q. The project I'm working on requires me to cut a fairly detailed design. The material I'm cutting is masking tape and I'll be cutting it while it's already applied on a spray painted surface. Which crafting knife and blade would be best for this project? I want to avoid making the tape peel along the cut lines that curves. I'm also worried about cutting to deep and leaving marks on the painted surface. I assume I need something that offers a lot of control and a very sharp blade. If you have any advice I would greatly appreciate it thank you! Michael, Los Angeles.

- Date: 25 Jan 2017

-

Enlarge Dear Michael, We appreciate your question. We would recommend the 10A surgical blade with the No.3 Handle if you are looking for control and dexterity however the most difficult issue is preventing you cutting too deep. The sharp tip of the blade will provide the precision you are looking for but might well damage the spray painted surface beneath. It might be worth experimenting with a curved blade shape such as the 10 so although you don't have the pointed tip you still have the surgical sharp cutting edge and you may be able to control the depth of cut better with the curvature of the blade. Again this would fit the No.3 handle. We do have other handles that fit these blades if you are looking for rotation movement which you might get with the [B3 Surgical Handle](http://www.swann-morton.com/product/52.php) or a larger grip like the [5A](http://www.craftknives.co.uk/product/acrylic-craft-handle-5a). These can be seen on our website and are all available in the US locally through Cincinnati Surgical who have a [Craft](http://www.csartsandcraftsproducts.com/) and an [Industrial](http://www.csindustrialproducts.com/) section to their own website and you can also purchase the product on line for your convenience. We hope we have at least provided you with some options which you can investigate further. - Q. I have bought a second hand box of knives for crafts but it had no instructions with it. Could you tell me what I would use each one for? One side of the box has all the blades in it placed on a magnet, the other side has all the handles - they are all different sized blades and different handles. Thankyou, I do hope you can tell me.

- Date: 20 Jan 2017

-

Enlarge Hi Patrisha, It sounds like our ACM set and it contains a number of different handle and blade combinations. This [link](http://www.craftknives.co.uk/product.php?id=6) provides an insight into some of the different usages however the preference lies with the end user as to which blade is used for which task. I hope the information on our website helps you better understand the product. - Q. I am looking to cut precisely into 1.4mm thick mount board for displaying photographs. I am unsure which product would best suit my needs?

The rounded handle seems to have mixed reviews with craft makers, however I was unsure whether it would provide the better weight to make the cut?

Any ideas would be greatly appreciated, Kayleigh. - Date: 19 Jan 2017

- HI Kayleigh. In the Graphic Design Industry the 10A blade mounted on a No.3 surgical handle became the standard trusted tool for cutting and pasting projects and they are still used to this day for making mock ups and models. It should be ideal for precise cutting of the 1.4mm thick mount board and they are available from most leading stockists or online at [scalpelsandblades.co.uk](https://www.scalpelsandblades.co.uk/). Thank you for contacting us and we hope we have been of assistance.

- Q. Hi, I have an ACM set used for craft bookbinding. I need to trim the edges of bookblocks held in a press. This needs the blade to have a clear depth of movement of 40-45mm clear of the blade grip and handle. The blades in the ACM set are about 10mm short of this requirement.

Do you have any blades or complete products that fit this requirement? I would appreciate any help you can provide. Regards, David - Date: 06 Jan 2017

-

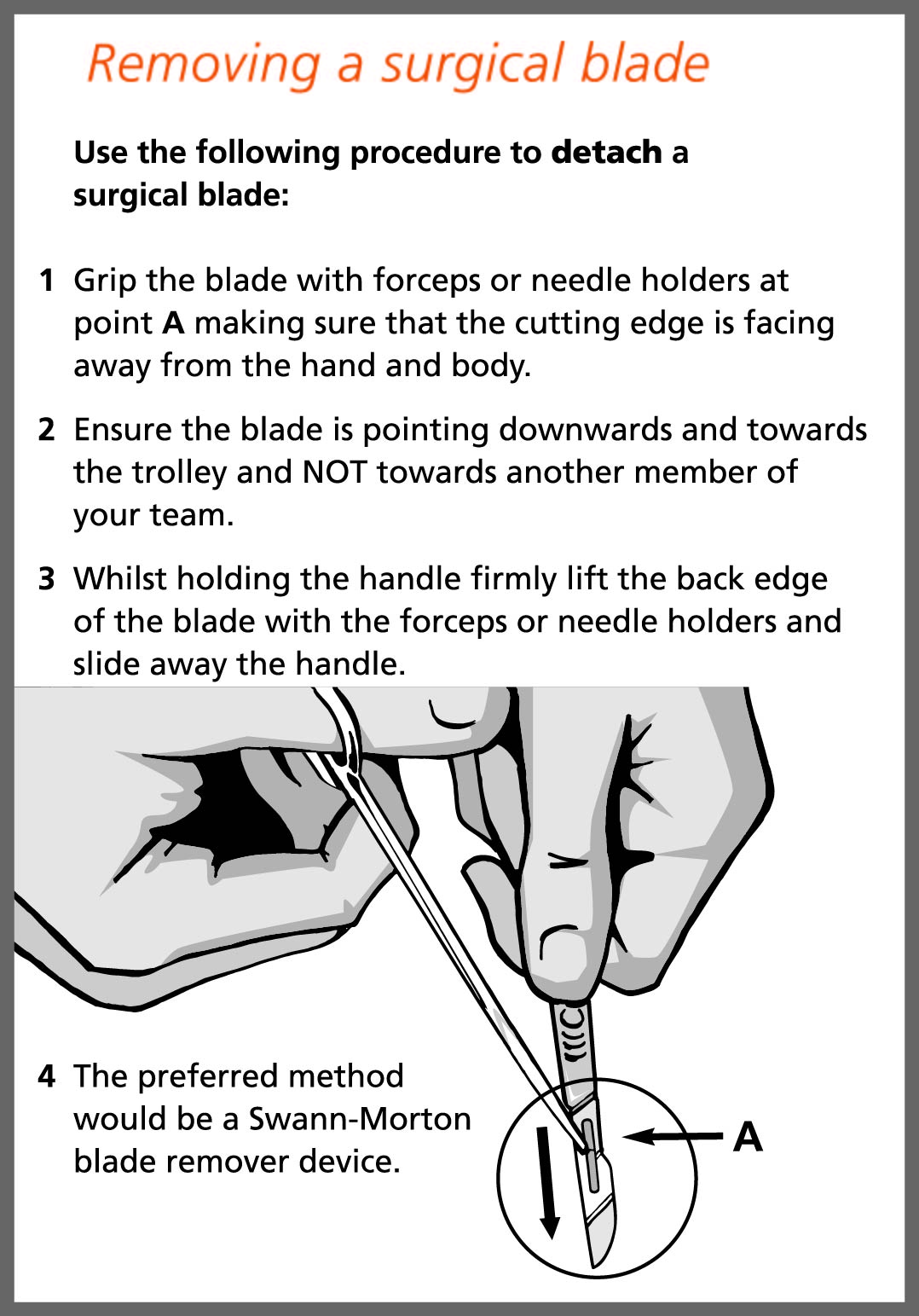

Enlarge We have measured some of the standard surgical blades however even the largest ones in the range would only have a clearance of 25-30 mm from the front end of the fitment. The only blade we can find that would have that clearance and more would be the [Post Mortem knife](http://www.swann-morton.com/product_range/10.php). Not exactly what they were designed for but it is a thicker blade so would have the additional lateral strength for cutting thicker materials. _____________ David's reply: I would like to thank you for the suggestions you made. I have tried a PM40 for bookblock trimming. The results are about as good as can be achieved with a professional bookbinding plough. I've tried it from 100 gsm paper up to 150 gsm card and it works without paper tearing or any sign of rough edges. The blade length is more than adequate for all the jobs I have in hand. I will pass on this information to the professional bookbinder I know who runs courses, because trimming is easily the most difficult task to perform well without expensive equipment. It is a fearsome implement and needs to be handled with great care. Am I right in thinking that the blades are too large for your standard blade disposal box? Do you have appropriate safe disposal procedures? I also use 10A blades and would ideally like to implement one procedure covering everything if possible. _____________ Further reply from Swann-Morton: Hi David, We are pleased the PM works well and yes it is fierce and you have to watch your fingers, however given its size, it is somewhat easier to get hold of the non-cutting edge in order to fit and dispose of it and to drop it out of the handle without touching it. There are various sizes of sharps containers so you would have to have larger one on hand. As for the smaller blades such as the 10A we have various information (see image) and also options on [removing the blade](http://www.swann-morton.com/view_reading.php?reading_id=1) as shown on our surgical website where there are also a number of [training films](http://www.swann-morton.com/interactive.php). We hope this helps. - Q. I attended the Warley Model Railway Exhibition a year or two ago, and you had a stand. I was informed that the old medical scalpel handles from my school dissecting kit are no longer considered suitable. (I have used them for over 30 years!).

I forget why they are considered unsuitable, do you think you should make this information more widely available on your website?

I have re-equipped and how should I best dispose of the handles in the UK? Thanks. - Date: 05 Dec 2016

- Dear Norman, This was more from a medical perspective than general use for hobbies and craft. In the hospital they were having increasing problems with nickel allergies amongst both staff and patients plus sometimes during the cleaning cycle the nickel from the handles would stain the stainless instruments being cleaned at the same time. To top it all off the price of Nickel suddenly rocketed which made it more cost effective to manufacture the Stainless handles that are in fact more hard wearing and should last longer. You can dispose of the handles at any metal recycling facility or check with your local council.

- Q. As these blades were created for use in surgical procedures and therefore discarded immediately I can understand the reasoning in not creating a "cover" for them.

With the insurgence of use by paper artists etc. who may use one blade for more than one session, is there now any thought being put into creating a cover?

I can see you had this question before, but the answer was to remove the blade. However for someone who does not want to remove it at once and instead wants to keep it safe for another time, what are the options, stab it into foam??

Anya. - Date: 19 Nov 2016

-

Enlarge Dear Anya, We would suggest using our [Premium Retractaway Handle](http://www.craftknives.co.uk/product/retractawaypremium) so the blade can be retracted safely when not in use and easily changed once it has run its course. The problem with guards is that although they protect the user from the blade when not in use and also protect the blade cutting edge there is always the potential for a sharps injury when replacing the guard over the sharp blade. Alternatively there is the [ACM Range of blades](http://www.craftknives.co.uk/range/acm/) that do have covers on the blades. I hope this answers your question. - Q. I have just returned to Aeromodelling after a lay off of many years.

As an old Sheffield lad I am very unhappy with all the knockoff rubbish knives, based on your own, available here, in Canada. Do you have a Canadian distributor?.

I don't want an American one as the price differences due to currency exchange rates, postage costs, customs fees and retail sales taxes add up to more than the item costs in many cases.

Thank you, Peter Snaith.

PS - the old brass handle knife was perfect when I was learning to butcher balsa as a lad. Do you still make them? I hope so. - Date: 25 Apr 2016

- Dear Peter, Our products are available locally through Canadian Hospital Specialties - yes I know they are a medical distributor but they have been willing to supply the local craft market in the past. Their telephone number is +1 905 825 9300. We discontinued the Brass Craft Tool Handle last year as we cannot get the raw material anymore in the format we need it. We are looking at launching a new Stainless Steel version later in the year so please keep an eye on our craft website at [craftknives.co.uk](http://www.craftknives.co.uk) Thank you for your kind comments and loyalty to Swann-Morton!

- Q. Are your Acm blades stronger and thicker than the surgical blades, and are just as sharp. Because I trim small pieces of wood, and wondered whether they would better than the surgical ones. Thanks.

Sorry forgot my other question, do have a cover for the blade on the 5A acrylic craft handle. - Date: 07 Apr 2016

-

Enlarge Hi Ray. Firstly you are correct the ACM blades are manufactured from a thicker gauge of steel so they are stronger than the standard surgical blade which is probably more appropriate for cutting light weight material and finer more detailed work. Sharpness is a perception and often whether something is "sharp enough" for the task at hand depends on whether the correct blade shape and size has been selected however the cutting edge should be consistent and durable on the ACM range and more appropriate for medium to heavy duty materials. Unfortunately we do not have a cover or guard for use with the 5A Acrylic handle. If you want to protect the blade when not is use then you need to look at the Retractaway premium knife. Thank you for contacting us and I hope we have answered your questions. - Q. Will Nº 23 blades fit Nº5A acrylic craft handle?

- Date: 13 Feb 2016

-

Enlarge Hi Clive and thanks for your question. The 5A acrylic craft handle has a No.3 fitting so unfortunately the No. 23 blades will not fit that handle. They will however fit the [6a acrylic handle](http://www.craftknives.co.uk/product/acrylic-craft-handle-6a) which has the No.4 fitting for the larger blades in our standard surgical blade range. - Q. Do you have a protective sheath to fit the No4 handle with a 25a blade attached, up to recently I have been using the orange handled one that had a sheath supplied with it but I find that this sheath is a bit loose when used with the No4 handle. Ed.

- Date: 05 Jan 2016

-

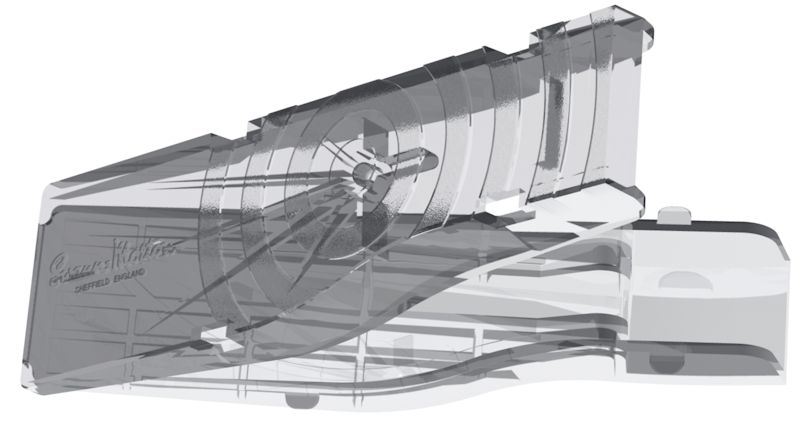

Enlarge Hi Ed, You are correct, the guard would be loose if used on a standard No.4 Handle as it won't grip the shaft once over the blade. I assume you have been using the red handled Trimaway knife which comes with the 25a blade fitted and a protective guard. Unfortunately we don't have a guard to fit over the standard blade and handle combination unless you use a plastic blade remover as shown in the image and just close it over the blade when not in use. - Q. What blades fit a No 5A craft knife? A. Maxwell

- Date: 04 Dec 2015

-

Enlarge Dear Mr. Maxwell, many thanks for your question about which blades fit the [5A Acrylic craft handle](http://www.craftknives.co.uk/product/acrylic-craft-handle-5a). The blade shapes which are compatible and popular for use with the 5A are: No.10, 10a, 11, 15 and 15A However it is also compatible with sizes: No.6, 9, 10, 11P, 12, 12D, 13, 14, 15C, 15T and 16 If you require any additional information then please do not hesitate to contact us again. - Q. Hi, I am a mature art student studying Jewellery at UCA Farnham and recently bought one of you most useful retractable scalpels for my tool kit.

My much younger fellow student who is from China fell on the tool and borrows it all the time. I offered to buy him one (he has no transport).

He glibly said they were probably made in China and he could get one cheaper there via the net.

With a sinking heart I nodded agreement.

I was delighted to find that you are a UK company and the product is manufactured here! I cannot wait to tell him and Im off to but him one this morning just so that I can point out made in UK.

Best wishes, Candy - Date: 25 Nov 2015

- Hi Candy, we're glad you and your Chinese fellow student enjoy using your UK made retractable scalpels!

- Q. I have a no 5 handle, its a longer, quite thin handle, I cant find it on your sites, can you tell me the correct blade for this handle please.

- Date: 25 Nov 2015

-

Enlarge Hi Paul, I think you will find the handle you are looking for at the link below on our surgical site. Probably 25 years ago now the designation for this handle was changed from 5 to 7 to encourage standardisation amongst surgical blade manufacturers across the World. [No. 7 Handle](http://www.swann-morton.com/product/121.php) Any of the No.3 fitment blades such as the No.10, 10a, 11, 12 and 15 will fit this handle. I hope this answers your question. - Q. Hi, I am doing paper cut art in Malaysia. While the recommendation of 10a and 11 are mentioned, I would like to know the actual dimension of the blade, the size etc. Is 15A smaller than 11. We have a visual idea how small the blade is once the dimension are known. Will the blade withstand cutting a curvature? The blades we use bends and times the tips break.

Thank you, Brinda. - Date: 08 Sep 2015

- Hi Brinda. The recommendations on the website are from other existing artists but as with all usage areas it comes down to personal preference. I have sent you a chart which although not actual size does give you more of idea of how big one shape is compared to another. The 15A is smaller than the 11 yet it has an unsupported tip. If you look at the top edge of the blade it is straight which means that although the tip is sharp there is not a lot of strength in it. At this juncture you have to bear in mind that these are actually surgical blades designed for 'downward cutting action into soft tissue' all other applications have arisen overtime. The 11 itself is 'backed off' meaning there is a slope or a curvature from the tip to the main run of the back edge of the blade. This provides more support to the tip making it stronger and this is why the 11 is often used in other light industrial applications. If however you want a really sharp tip then the 11P (P is for pointed) is best but again the tip would snip off if cutting down onto a hard surface. If cutting down it is important to use a cutting mat not a hard surface such as glass or metal as this will not only damage the cutting edge meaning you will need more blades to complete the project but again the tip may snip off when contacting the hard surface. Placing lateral pressure on the blade when making a curved cut should not break the blade providing it is kept within reasonable parameters. The blade is designed to allow some lateral pressure however if excess force is applied laterally, being metal, it will at some point cause the blade to fracture and worse still break. As we said remember a downward incision into soft tissue does not usually involve any lateral pressure being applied so is the blade fit for purpose as you may be using it outside its design parameters. For cutting a curvature maybe the hooked No.12 blade would be more appropriate as again this is used in certain light industrial applications such as Jewellery manufacture for keying the moulds. I hope you find this information useful and you will enjoy using our products in your papercutting projects.

- Q. Please could you advise me on which scalpel I should buy as I am going to be studying Textiles at university and have been asked to buy an assortment of blades. Thanks, Imogen.

- Date: 10 Aug 2015

-

Enlarge [Claudette Cooling](http://www.craftknives.co.uk/articles.php?project_id=5) has always used the no. 10a & no. 11 blades with a No.3 handle. This combination has worked well for her on many different materials from mount board to leather and she has never had any problems. All universities advise you to get a range of blades. If you are going for cheap and cheerful blades then yes you will need an assortment because the cheap blades snap under any type of pressure, but in her opinion by choosing quality blades like Swann-Morton the no. 10a & no. 11 should be sufficient for all you need to do. She hopes you have a fabulous experience and start to your new university course! - Q. Hello,

I am starting up paper cutting and wondered which knives you would recommend for this craft, bearing in mind I will be a complete beginner. Kind Regards, Kay. - Date: 28 Jul 2015

-

Enlarge Hi Kay, it would appear that the blade of choice for the Paper Cut artists is the 10a combined with the No.3 Surgical Handles. To begin with you can buy this as a carded set from reputable online outlets then just order in extra blades as you need them. - Q. Hi, I am just wondering how long the little orange plastic craft knife has been in production by Swann Morton, I can't remember a time when they weren't available!

- Date: 16 Jul 2015

- Yes the orange craft tool handle seems to have been around for ever and we are pretty sure it was first launched back in the 1950's. The original version was in fact black! A good example of something quite simple that is "fit for purpose".

- Q. I need a good knife for cutting dollar tree foam board. What handle and blade would you recommend? Thanks, Phil Lyons

- Date: 30 Apr 2015

-

Enlarge Hi Phil, that's an excellent question! We would suggest a No.11 Surgical Blade (0103) on a No.3 Handle (0933) or a Retractaway Premium Handle (2806) however having researched this on the internet it seems essential that you cut down onto a cutting mat rather than a hard surface to get a clean cut through the lower layer of paper. You could alternatively use one of our ACM No.11 blades (9303) with the ACM No.1 handle however I feel the surgical cutting edge on this occasion will outperform the ACM blade. Assuming you are based in the USA, all our products can be [purchased online here](http://www.cincinnatisurgical.com/arts.lasso) Thank you for the enquiry. - Q. Hi, what would be best for cutting medium thickness photo paper?

Cheers, Joe. - Date: 21 Jan 2015

- Hi Joe, thanks for your question. We would recommend the 10A blade as this seems to be the most popular product used by graphic artists.

- Q. I order retractable knives for hallmark creative studio and have been asked to source a left handed retractable salpel.

- Date: 05 Nov 2014

- Hi Joan and thanks for your question. I would have thought you could use the Retractaway or the Retractable scalpels left handed without it effecting performance and dexterity. It may be harder for a left-handed person to load the blade but this is just speculation.

- Q. Hello, I am a paper-cutting artist and was hoping you may be able to recommend a knife and blade for extremely fine paper cutting (perhaps a very small blade?..)

thank you for your consideration.

Sincerely, Bryan Zimmerman - Date: 05 Nov 2014

-

Enlarge Hi Bryan, I would still edge towards a 10A blade as it has always been used in graphics. - Q. Hi, ORANGE PLASTIC CRAFT TOOL - CLARIFICATION NEEDED

This may sound like a daft question:

The handle has a hole drilled into it for the nut and bolt to hold the blade into place when tightened. On one side of the handle, the hole has a larger recess, is this to account for the collar protruding from the nut which if inserted this way will accommodate the collar and both nut and bolt will meet flush with the plastic handle perfectly when tightened.

I ask this as i am supporting disabled people with the job of inserting the nut and bolt into thousands of handles and want to make sure we are doing this task correctly as you will be collecting the finished handles at some point.

In short, does it matter which side of the handle the nut and bolt is inserted? or shall I continue with my instincts?

Ray - Date: 22 Oct 2014

- Hi Ray, it's not a daft question at all! I have checked with our production department and from an assembly point of view it doesn't actually matter as the craft tool is disassembled again at the next stage of production. However, from a user's point of view is does have to be flush.

- Q. I am looking for a supplier of scalpel blades in Arizona for number 5 and 6, BP handle. I am a model maker, now retired, looking for a few blades I have run out of. I have both handles but couldn't find a supplier in the Phoenix area. Help. William.

- Date: 11 Sep 2014

-

Enlarge Hi William, we should be able to help you out there. We have a long established supplier of our products in the USA and I'm sure they will be able to supply what you need. They are called Cincinnati Surgical Arts and Crafts - you can [visit their website here](http://www.cincinnatisurgical.com/arts.lasso) - Q. I have an ACM no.1 handle. Do I need to purchase the ACM blades or will standard blades also fit this handle (specifically the 10A)?

Thanks, Simone - Date: 07 Sep 2014

-

Enlarge Thanks for your excellent question Simone. You will definitely need to purchase the ACM blades as they are designed to fir the ACM handles. Standard blades like the No. 10A may not fix in the handle correctly. - Q. Having recently purchased one of your beautifully made No3 Handle craft tool from my local Axworthy's with separate pack of no.11 blades, I was left feeling something was missing. And of course there is - a sheath to cover the lethal blade which I carefully inserted into the handle. So I am now left with a storage problem and wondering what to put on the end of the blade. Has this never been thought of? Thank you in advance of your reply. Hilary.

- Date: 21 Jul 2014

- Many thanks for your question Hilary. Safety and scalpel blades go hand in hand - may we suggest you use a [Blade Remover](http://www.swann-morton.com/product/116.php) clasped across the open blade or the [retractaway handle](http://www.craftknives.co.uk/product/retractaway) would be the best option.

- Q. I have recently bought a Single-use Blade Remover which came without instructions for use. The locating tabs do not appear to be that robust and so I am reluctant to take it apart unnecessarily. would you please give me some guidance, thank you, Brian.

- Date: 04 Jun 2014

-

Enlarge Thanks for your question Brian. We recently added some new videos to the Interactive section of our website. One of the videos is on the Single Use Blade Remover you have enquired about. You can view it here: [Single Use Blade Remover](http://www.swann-morton.com/view_video.php?video_id=19). I hope this answers your question. - Q. What is difference in thickness of the trimaway blade variants (10A and No. 11) compared to the surgical blades

- Date: 09 Apr 2014

-

Enlarge Hi Simon and thanks for your question. The Trimaway has a thicker medium duty 25A blade on it as does the Trimaway 01 which has an Industrial 01 blade on it. The 10A and 11 blades which fit the Retractaway are standard thickness surgical blades (no variation). - Q. Where can I purchase some of your blades 10A for one of your small black sliding blade knives - which is excellent is all respects -

I do not know how to obtain some of these blades - they are definitely 10A on the bottom of the blade - thanks very much. - Date: 06 Apr 2014

-

Enlarge Hello Mr Scoffin and thanks for your question and kind comments. The black handle you refer to is our Retractaway and you can order the blades to fit it (10A, 11, etc.) online from one of our stockists at [Scalpels and blades](http://www.scalpelsandblades.co.uk/) or alternatively from [Hannants](http://www.hannants.co.uk) on 020 8205 6697 or by email to: [colindale@hannants.co.uk](mailto:colindale@hannants.co.uk) - Q. I have been recommended a no 15 blade for erasing ink on paper re calligraphy. I would prefer to add this to a retractable handle if possible . Could you advise please if possible which to buy. thank you.

- Date: 11 Feb 2014

-

Enlarge Hi Deborah, thanks for your question. We would recommend that you purchase a [Retractaway handle](http://www.craftknives.co.uk/product/retractaway) This is compatible with the number 15 blade - Q. Is there a suitable blade that would cut fabric i.e. to use with paper patterns to cut out fabrics for tailoring etc

- Date: 02 Dec 2013

-

Enlarge Thanks for your question Margaret. We would recommend the [Trimaway](http://www.craftknives.co.uk/product/trimaway) This has a thicker blade and could be more suited to your needs than a standard surgical blade. For cutting the paper patterns we would recommend the 10A blade as this has been used for many years by graphic artists. Also the no. 11 blade would be suitable as this is recommended by papercut artists. - Q. Do you have anything showing the application/purpose of the different shaped blades in your ACM kit? Thanks, Paul.

- Date: 11 Nov 2013

- Thanks for your question Paul. There's some information under [Community Pages, common usage](http://www.craftknives.co.uk/usage.php). Here's a summary: The following blades fit the ACM No. 1 Handle: ACM No.10 Blade - General cutting and light carving. ACM No.11 Blade - Light weight materials, trimming and high precision cutting. ACM No.16 Blade - Stenciling,scoring and etching blades. ACM No.17 Blade - Chiseling blade for light weight materials. The following blades fit the ACM No. 2 Handle: ACM No.2 Blade - High precision cutting of medium and heavy duty materials. ACM No.18 Blade - Deep cross cutting and smooth chiseling blade. ACM No.22 Blade - Carving blade for medium and heavy duty materials. ACM No.24 Blade - Corner cuts, deburring, stripping and gasket cutting. ACM No.28 Blade - Contour and shaping blade.

- Q. We are often asked what is the best tool for the job?

- Date: 28 Jun 2013

- Maybe this link will help you to decide. [YouTube](http://www.youtube.com/watch?v=hiT9XVd7TKM)

- Q. Do you have a stand, like for cutlery, to store the scalpels with blade?

- Date: 29 May 2013

- We don't have anything specific to store the scalpels/blades whilst in use but whatever you use you need to make sure they don't come in contact with the cutting edge as this will have an adverse affect on the durability and performance of the blade.

- Q. Is there a safe or enviromental way to dispose of used blades as I am reluctant to throw them away with my household rubbish?

- Date: 01 Apr 2013

-

Enlarge Hi Donna and thanks for your question. You are quite right, you shouldn't dispose of sharps in household rubbish from a health and safety perspective as well as for environmental reasons. You should invest in a sharps box or container to keep your used blades in then once it is full you can contact your local council who should be able to advise you on your local disposal point. You can usually buy the sharps boxes online via E-bay or Amazon however our associates at [Jewel Blade](http://www.jewelblade.com/key_contacts.php) offer a range of these boxes and should be able to advise you where to source one locally. - Q. Please can you tell me if you do thick handled craft knives? My dad loves carving but is finding it difficult to hold thin handles. Could you recommend one? Thank you.

- Date: 25 Mar 2013

-

Enlarge Thanks for your question Sue. We would recommend the [Acrylic 5A](http://www.craftknives.co.uk/product/acrylic-craft-handle-5a) and [6A](http://www.craftknives.co.uk/product/acrylic-craft-handle-6a) handles. These can be purchased as part of a carded set including a few blades or individually so you can buy your blades separately. - Q. Do Swann-Morton have any knives that have a retracting blade for safe storage or when carrying it. ?

- Date: 05 Feb 2013

-

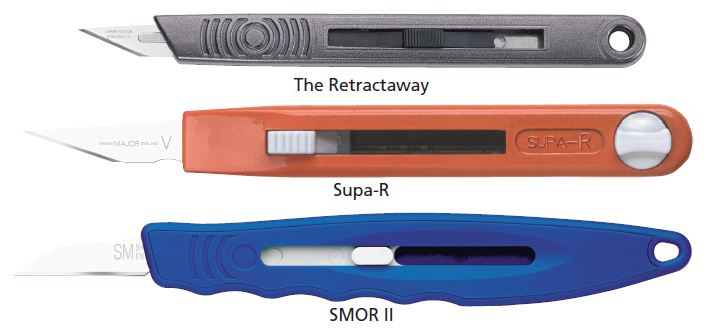

Enlarge Depending upon the usage area we do have several knives that have a retractable blade. The Retractaway knife is popular amongst the Arts, Craft and Modelling user groups whilst for light industrial applications or for cutting thicker material we have the Supa-R and the relatively New SMOR II knives with a selection of blade shapes. Please refer to the [product section](http://www.craftknives.co.uk/products.php) for more information. - Q. Can I buy my Swann-Morton craft products on-line?

- Date: 05 Feb 2013

- Although Swann-Morton themselves do not sell products online there are a number of companies and resources that can be found on the internet from whom you can buy our products. Please research your source before placing an order to ensure they appear reputable as we cannot be held responsible for any faulty, expired or counterfeit products supplied via this route. Please also visit the [distributor section](http://www.craftknives.co.uk/distributors.php) of this site.

- Q. How do I change the blade on my Craft Tool Knife ?

- Date: 05 Feb 2013

-

Enlarge Loosen the metal screw ensuring you do not remove it totally from the handle. Slide your blade into the gap which you have now opened up at the front of the handle. Once the blade is in place tighten up the screw to hold it firmly in place during use. Please note the screw does NOT fit through the hole in the blade. - Q. How do I change the blades on my ACM Knife?

- Date: 05 Feb 2013

-

Enlarge Twist the knurled collar clockwise to loosen the handle and pull out the old blade avoiding the cutting edge. Insert a new blade and turn the collar anti-clockwise to tighten. Always hold the knife handle with the blade pointing away from yourself. - Q. How do I remove a blade from my Retractaway Knife ?

- Date: 05 Feb 2013

-

Enlarge Fully extend the handles blade carrier using the side trigger. Grip the blade with pointed pliers halfway between tip and blade stop, avoiding the cutting edge. With your index finger end, lift base of blade over locating slot and ease it off with pliers. - Q. How do I fit a blade to my Retractaway Knife ?

- Date: 05 Feb 2013

-

Enlarge Fully extend the handles blade carrier using the side trigger. Grip the blade with pliers avoiding contact with cutting edge. Slide the blade into position on blade carrier until the slot locates fully over blade stop and clicks into position. Retract the carrier back using the side trigger into the mid- usage position. When not in use retract the blade fully back into the handle for safety from sharps injury. - Q. How do I fit a blade to my Swann-Morton Professional Range Handle ?

- Date: 18 Jan 2013

-

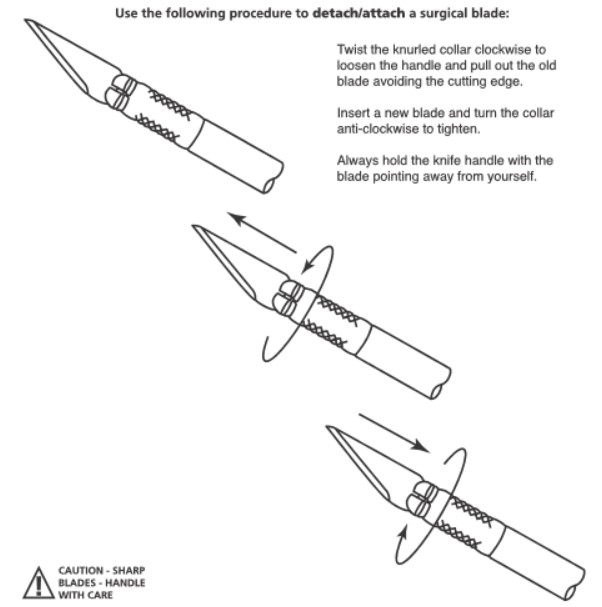

Enlarge Use the following procedure to attach a surgical blade: 1. Grip blade with forceps, or similar, avoiding contact with cutting edge. 2. Hold handle in left hand with bayonet fitting uppermost. 3. Place blade partway over handle fitting and engage slots. 4. Slide blade until it clicks into position. 5. To improve assembly, flex blade slightly upwards when sliding onto the handle